Why Direct to Film Transfer Designs Matter Before You Press Print

Know more about Why Direct to Film Transfer Designs Matter Before You Press Print

" class="img-responsive center-image" alt="Why Direct to Film Transfer Designs Matter Before You Press Print"/>

" class="img-responsive center-image" alt="Why Direct to Film Transfer Designs Matter Before You Press Print"/>

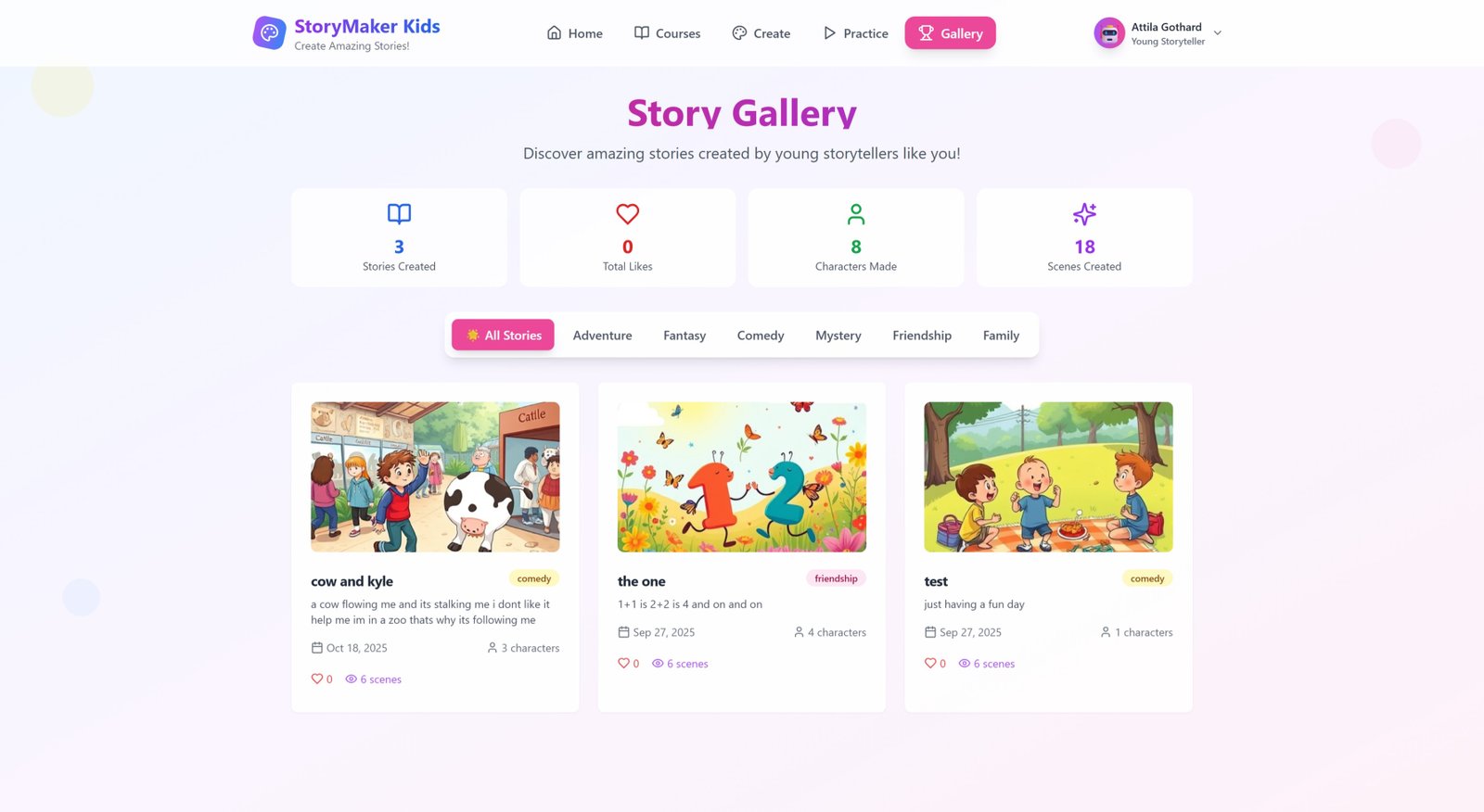

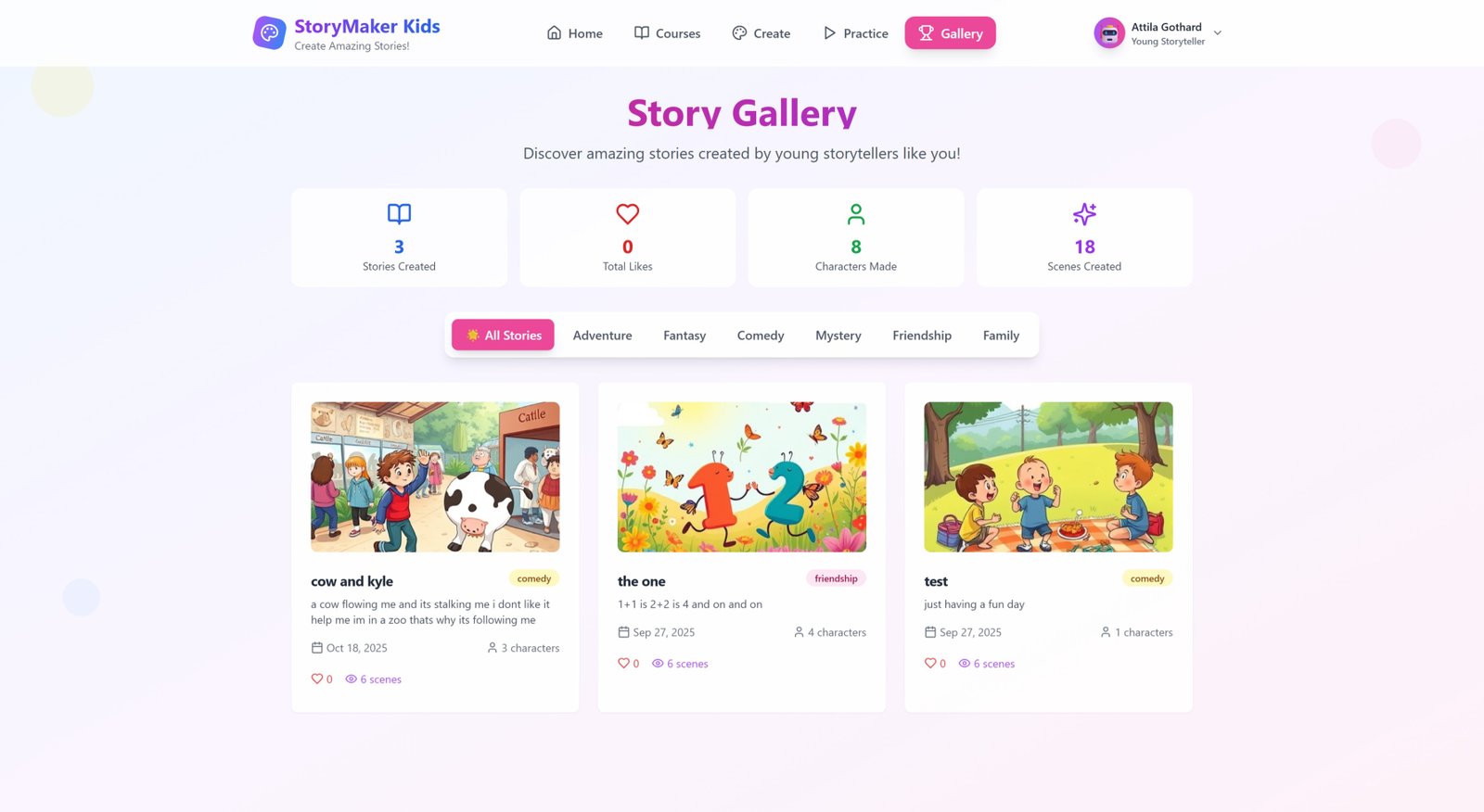

Most shops think problems start at the printer. They don’t. They start in the file. In DTF printing for custom apparel, the design controls everything—color strength, adhesion, stretch, and wash life. If the artwork isn’t built for production, no machine can fix it later. That’s why mastering direct to film transfer design tips is not optional. It’s operational discipline.

Good design reduces reprints. It protects margins. It delivers professional DTF printing results consistently. Before you load film. Before the powder hits the ink. Focus on the artwork.

Essential Direct to Film Transfer Design Tips

Here are practical DTF design tips for apparel printing that improve output and reduce risk:

-

Design at 300 DPI (Final Size Only): Never upscale. Low resolution kills edges and fine details. This is one of the basic DTF printing design guidelines.

-

Work in CMYK, Not Just RGB: Screens lie. Fabric tells the truth. Convert early for better DTF print quality optimization.

-

Use Vector Files When Possible: Vectors keep logos and text sharp. Clean edges = clean transfers. Critical for DTF transfer artwork preparation.

-

Remove Backgrounds Completely: No white boxes. No hidden fills. Transparency improves flexibility and comfort.

-

Control Line Thickness: Ultra-thin lines crack and disappear. Build designs that survive powder and press.

-

Avoid Heavy Solid Blocks: Large ink fills feel stiff. Break them into textures for better stretch and durability.

-

Test Halftones Before Production: Halftones reduce ink load, but dot size must be right. Smart halftones improve comfort and finish.

-

Leave Space on Gang Sheets: Crowding saves film but hurts pressing accuracy. Clean layout supports smoother production.

These are not cosmetic tweaks. They are DTF transfer design best practices that directly impact wash durability and customer satisfaction.

Print Location vs Placement vs Print Size

Design is not just about artwork. It’s about where and how it lives on the garment.

Print Location is the chosen area: left chest, full front, upper back, sleeve. Each location serves a purpose. Branding. Statement graphics. Secondary identity. Choose based on intent, not trend.

Placement is alignment. A design can be centered by measurement and still look wrong visually. Bodies are not flat canvases. Shoulders slope. Fabric drapes. Good placement balances the human form, not just grid lines.

Print Size controls comfort and perception. Oversized prints feel heavy and trap heat. Too small, and details vanish. Scaling must change with garment size. One fixed dimension across S to 3XL is a production mistake.

In designing artwork for DTF printing, these three elements work together. Miss one, and even technically correct prints look unprofessional.

Conclusion: Design First. Print Second.

The quality of high-quality DTF printing is decided long before the heat press closes.

Strong files. Proper color handling. Balanced ink usage. Thoughtful placement. These are not optional steps—they are competitive advantages.

If you want consistent output in DTF printing for custom apparel, start with disciplined design. Follow proven direct to film transfer design tips. Build files for durability, not just appearance.

Next step? Audit your last five designs. Check DPI. Check color mode. Check placement logic. Fix what’s weak.

Because in DTF, design is not decoration. It’s production strategy.

', 'Share This Post', 'width=640,height=450');return false" class="btn-share share pinterest">

Pinterest

', 'Share This Post', 'width=640,height=450');return false" class="btn-share share pinterest">

Pinterest

What's Your Reaction?