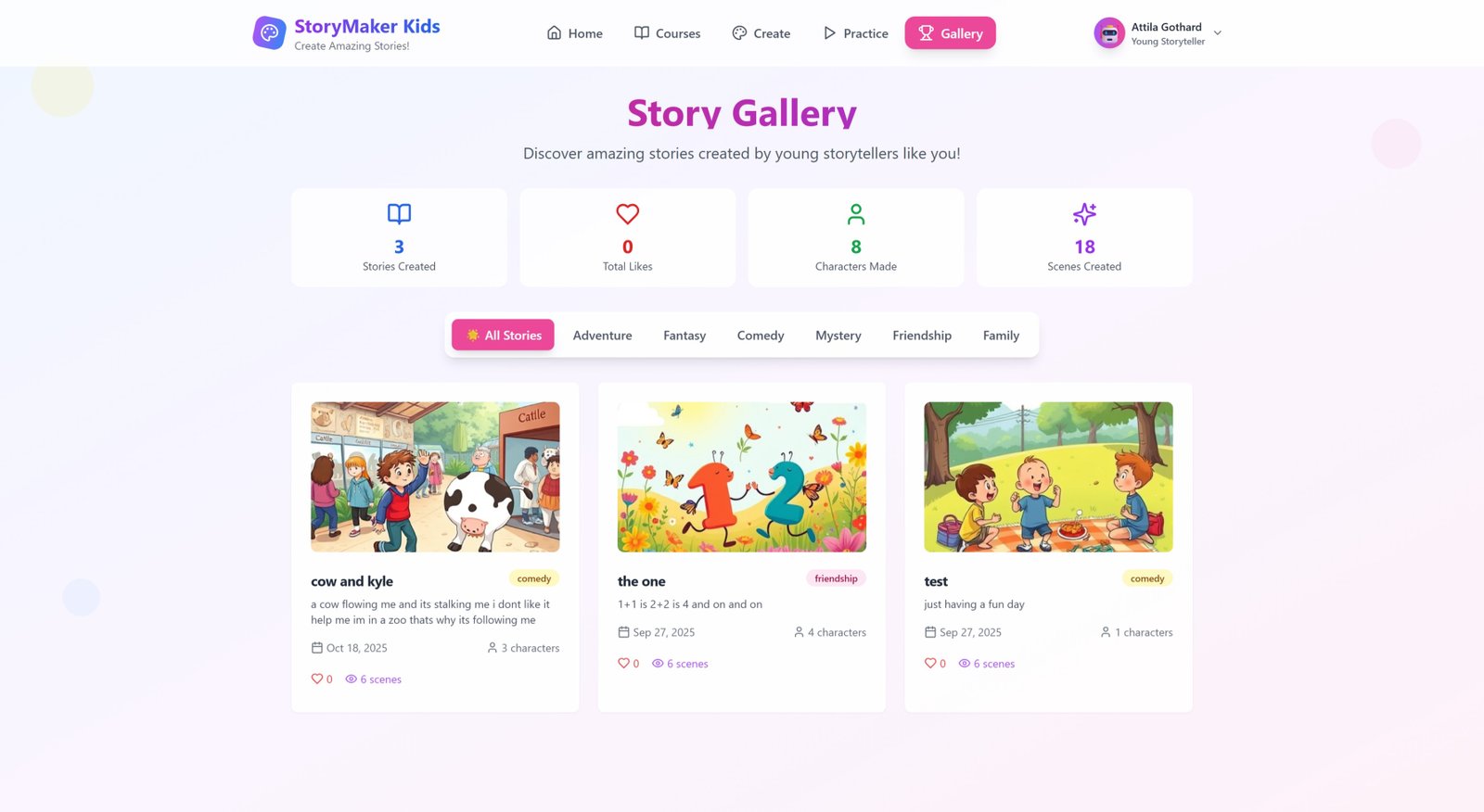

Direct to Film vs Heat Transfer: A Real-World Comparison That Actually Matters

Direct to Film vs Heat Transfer isn’t about trends—it’s about workflow, cost, and scalability. Compare DTF and heat transfer printing to choose the right method for your apparel business.

" class="img-responsive center-image" alt="Direct to Film vs Heat Transfer: A Real-World Comparison That Actually Matters"/>

" class="img-responsive center-image" alt="Direct to Film vs Heat Transfer: A Real-World Comparison That Actually Matters"/>

If you are in the business of printing designs on apparel, mugs, hoodies, or t-shirts, you must have faced the direct to film vs heat transfer dilemma. While both offer their own advantages and disadvantages, choosing the right printing method is critical for costs, quality, and business growth.

Choosing between direct to film and heat transfer is not about trends. It’s about workflow. Margins. Stress. And how fast your shop can move without breaking things. Both methods work. Both fail when misused. The difference shows up when orders pile up. Let’s break it down.

First, a quick baseline.

What is Direct to Film printing?

DTF printing involves printing designs onto special film, applying adhesive powder, curing it, and then heat pressing it onto garments. You don’t print on fabric first. You use DTF transfer sheets. That’s the core shift.

What is Heat Transfer Printing?

Heat transfer relies on vinyl or printed transfers that are cut, weeded, and pressed directly onto garments. Simple. Manual. Familiar.

Now the real comparison.

Direct to Film vs Heat Transfer: A Quick Comparison

Design Flexibility and Print Output

This is where DTF vs Heat Transfer starts to split.

DTF prints what you design. Full color. Gradients. Fine lines. No layers. No shape limits. If your artwork is complex, DTF keeps it intact. This is one of the biggest DTF printing advantages.

Heat transfer vinyl works by cutting shapes. Every color is separate. More detail means more weeding. More time. More mistakes. The output is clean but limited.

If your business sells branding-heavy apparel or creative designs, DTF gives you freedom. If you sell names, numbers, and bold logos, heat transfer still holds ground.

Cost Structure and Profit Reality

Upfront cost scares people. Understandably.

DTF requires investment. Printer. Ink. Film. Powder. Curing setup. But once running, cost per print stays steady. You can print one shirt or fifty without wrecking margins.

Heat transfer looks cheaper. Vinyl is affordable. Equipment is minimal. But labor costs hide in plain sight. Weeding time adds up. Complex designs eat profit fast.

For growth-focused shops, DTF wins on long-term control. For very small, predictable orders, heat transfer stays lean.

Production Speed and Workflow

Speed isn’t just how fast you press. It’s how flexible your workflow is.

DTF separates printing from pressing. You can print transfers in batches. Store them. Use them later. That’s huge during rush periods.

Heat transfer follows a straight line. Cut. Weed. Press. Repeat. Every order depends on hands-on work. That limits volume.

If your orders change daily, DTF adapts better. Heat transfer prefers calm, repeat-heavy workflows.

Durability and Fabric Compatibility

Both methods last when done right.

DTF durability depends on curing. Get it right, prints stretch and hold color. Rush it, they peel.

Heat transfer vinyl bonds strongly but sits on top of fabric. It can peel if overstretched or applied poorly.

Fabric matters too. DTF works on cotton, polyester, blends, light or dark. No pretreatment.

Heat transfer prefers flat, stable fabrics and needs testing per material.

Mixed orders? DTF simplifies life.

Scalability and Daily Operations

This is the quiet deal-breaker.

DTF scales. You add printers. Improve batching. Automate curing. Labor doesn’t rise at the same speed.

Heat transfer hits a ceiling. Manual steps become bottlenecks. Training becomes overhead.

Maintenance differs too. DTF needs cleaning and discipline. Heat transfer is cleaner and simpler day to day.

Final Take

Direct to Film vs Heat Transfer isn’t about which is “better.” It’s about fit. DTF fits growth, variety, speed, and modern demand. Heat transfer fits simplicity, low entry cost, and controlled output. Choose based on how your business actually runs. Not how it hopes to.

Also read: How Custom DTF Transfers Work (Fast & Durable Prints!)

', 'Share This Post', 'width=640,height=450');return false" class="btn-share share pinterest">

Pinterest

', 'Share This Post', 'width=640,height=450');return false" class="btn-share share pinterest">

Pinterest

What's Your Reaction?

" alt="Why Direct to Film Transfer Designs Matter Before You Press Print" class="lazyload img-external" onerror='https://likelylike.com/assets/img/bg_slider.png' width="650" height="433">

" alt="Why Direct to Film Transfer Designs Matter Before You Press Print" class="lazyload img-external" onerror='https://likelylike.com/assets/img/bg_slider.png' width="650" height="433">