How Should Teams Inspect A Portable Distribution Box Before Each Event

Covers visual checks for heat signs loose fasteners and gasket integrity plus logging inspections. A practical angle for supervisors coordinating multiple sites with rotating staff.

When a Portable Distribution Box appears at a street market or a live outdoor stage, the scene hums with practical energy and imminent activity. Yet beneath the buzz lies a handful of common mistakes that can turn a useful piece of equipment into a safety hazard. Organizers, vendors and rental teams who spot and correct these faults protect attendees and avoid interruptions that can ripple through an entire production.

First, improper grounding remains a frequent oversight. A secure earth connection is not decorative; it controls stray currents and gives protective devices a clear path to operate. Ensuring bonding points are tight and that the ground conductor follows a tidy route reduces the chance that a live fault will create a touch hazard for staff or visitors. A quick check during setup is a small investment that avoids complex follow up later.

Second, overloads from poor load management often create trouble. When circuits are shared without clear labels or when heavy devices are plugged into the same channel, protective devices may operate and stall service. Planning power distribution with awareness of equipment draws and distributing heavy appliances across separate channels prevents nuisance trips and reduces the temptation to bypass safeguards.

Third, neglecting weather protection puts gear and people at risk. Boxes that face moisture or dust require appropriate closing methods and seals. Simple measures such as verifying gland integrity, keeping spare covers, and positioning the unit under a modest shelter preserve internal components and reduce short circuits caused by rain or spattered liquids. Temporary tarps are a stopgap but a proper rated enclosure is a safer choice.

Fourth, cable routing errors create tripping and strain hazards. Running leads across walkways or leaving splices exposed invites accidents and damages connectors. Use raised trays, secure clips, and visible ramps to protect runs while keeping pathways clear. Strain relief at cable entries prevents tension at terminals that can loosen screws and elevate contact resistance over time.

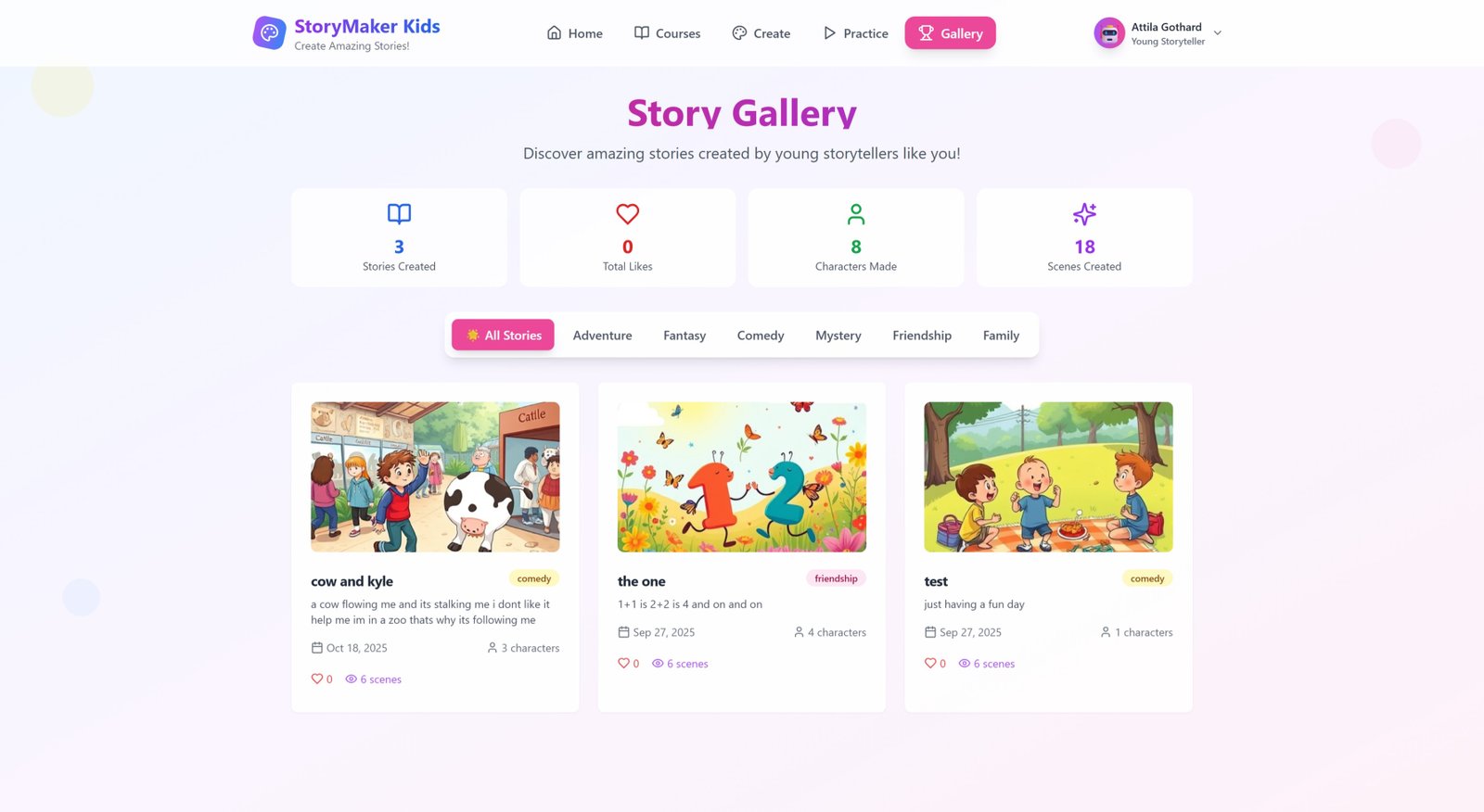

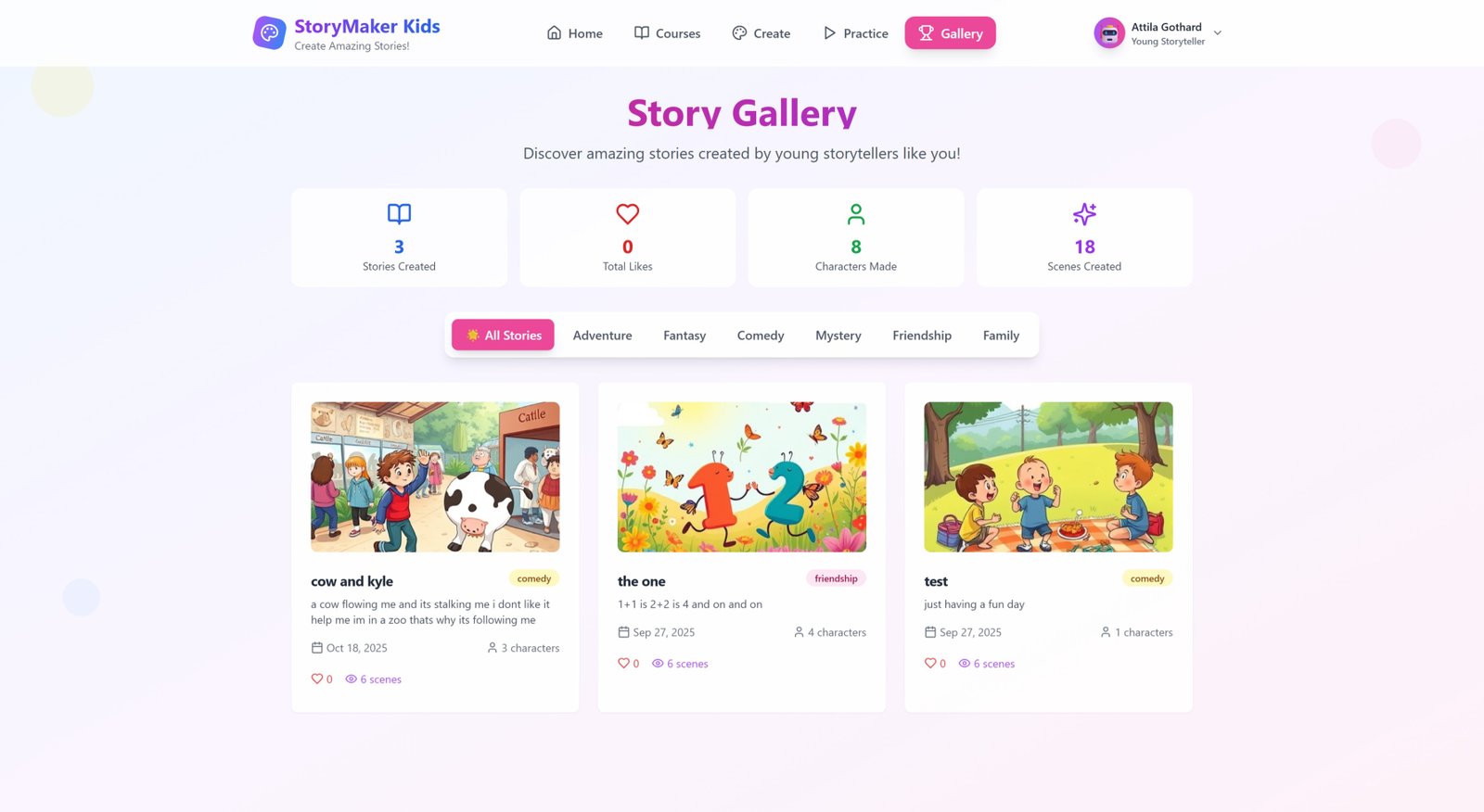

Fifth, lax inspection and documentation slow response when problems do occur. Routine checks that include visual signs of heat damage, loose fasteners and compromised seals let teams act before faults escalate. A brief log of who inspected what and when shortens handover between shifts and makes it easier to track recurring issues that need a permanent fix rather than repeated temporary repairs.

Beyond correcting these five pitfalls, training and simple process design strengthen safety culture. Brief orientation for volunteers and casual staff on safe connection practice, where spares live and when to call a qualified technician reduces risky improvisation. Clear labeling, photos in a service folder and a compact spare kit supported by a checklist turn reactive behavior into predictable routines.

Equipment choice matters too. Selecting a distribution unit with accessible terminals, protected outlets and clear, durable markings speeds setup and lowers the chance of human error. When procurement matches actual use patterns of markets festivals and catering zones, crews spend less time improvising and more time delivering services to visitors.

Finally, plan for incident response. Even with careful preparation, faults can happen. A rehearsed sequence that isolates the affected channel, replaces suspect parts from an on site kit and logs the event keeps disruptions short and helps organizers recover quickly. That same approach supports better communication with local authorities and rental partners when regulators or clients inquire after an unusual event.

Practical preparation prevents needless outages and reduces risky improvisation under pressure. Portable distribution devices are powerful enablers for lively events, but they require thoughtful handling. When organizers combine sensible gear choices with routine checks neat wiring and basic crew training, the result is smoother programming and safer public spaces. For a closer look at configurable units and options that help crews avoid these common pitfalls consult supplier materials and product notes at https://www.nante.com/ which provide configuration details and practical advice to support safe deployment and straightforward upkeep.

What's Your Reaction?