In the evolving world of textile manufacturing, textile fabric printing machines have become pivotal for producing high-quality fabrics with intricate designs and vibrant colors. These machines play an essential role in industries ranging from fashion to home decor, providing manufacturers and designers with diverse printing options tailored to their specific needs. This guide aims to provide an in-depth understanding of textile fabric printing machines, with a particular focus on the latest innovations and the growing market for Digital Textile Printer in Surat, one of India's leading textile hubs.

What Are Textile Fabric Printing Machines?

At its core, a textile fabric printing machine is equipment designed to apply color and patterns onto fabric surfaces. Unlike simple dyeing methods, printing allows the creation of precise designs and motifs in a variety of colors. These machines come in many forms—from traditional screen printing setups to modern digital textile printing systems—and cater to different fabric types, production volumes, and design complexities.

Types of Textile Fabric Printing Machines

The types of textile fabric printing machines vary widely depending on the technology used. The most common categories include:

1. Screen Printing Machines

This traditional method uses stencils (screens) to apply ink onto fabric. Each color requires a separate screen, making this process ideal for bulk production with limited colors. Screen printing machines can be manual or automatic and are known for their durability and vibrant color output.

2. Rotary Screen Printing Machines

A more advanced form of screen printing, rotary machines use cylindrical screens that rotate while fabric moves beneath them. This method is efficient for continuous or large-scale printing runs with multiple colors.

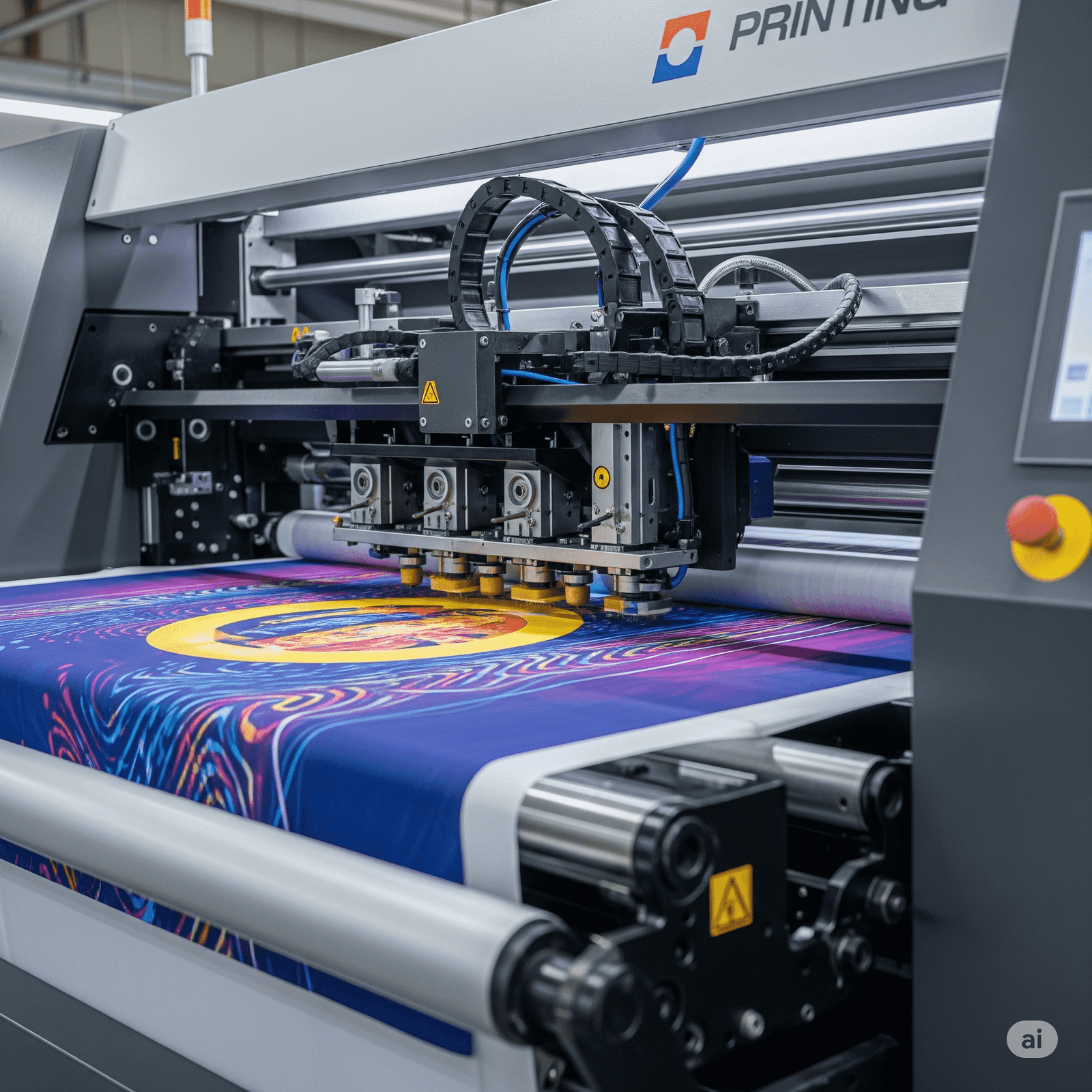

3. Digital Textile Printing Machines

The most modern and innovative category, digital textile printing machines use inkjet technology to print designs directly from digital files onto fabric. These machines support unlimited colors and complex patterns, allowing for on-demand and customized printing. Because there is little setup time, they are increasingly popular for both small and large-scale production.

Advantages of Digital Textile Printing Machines

Digital printing offers compelling benefits over traditional printing techniques:

- High Design Flexibility: Complex patterns, gradients, and photo-realistic images can be printed with ease.

- Quick Turnaround: Minimal setup time means faster production cycles.

- Cost-Effective for Small Batches: No screens or plates are needed, reducing costs for customized or short runs.

- Eco-Friendly: Uses less water and produces less waste, aligning with sustainable manufacturing goals.

- Wide Compatibility: Effective on diverse fabric types such as cotton, silk, polyester, and blends.

The Role of Surat in Digital Textile Printing

Surat, known as the textile capital of India, is at the forefront of adopting and advancing textile digital printing technology. The city's textile manufacturing community is rapidly integrating Digital Textile Printer in Surat to meet growing market demands for personalized, fast, and eco-friendly fabric printing. With access to skilled technicians, innovative machinery suppliers, and robust supply chains, Surat is developing into a leading center for digital textile printing solutions.

The adoption of digital printing in Surat helps textile businesses reduce production costs, offer quick customization, and meet global quality standards, fostering competitiveness in both domestic and international markets.

How Textile Fabric Printing Machines Work

While each machine type operates differently, the general workflow involves preparing the fabric, applying the design, and curing or fixing the print to ensure durability.

For Screen Printing

The fabric is positioned, and the screens with pre-set patterns ink are pressed against the fabric to transfer colors layer by layer.

For Digital Printing

A digital file of the design is fed to the printer, which uses nozzles to spray ink droplets in the exact pattern onto the fabric. After printing, the fabric is treated with heat or steam to fix the colors, ensuring wash-fastness and longevity.

Choosing the Right Textile Fabric Printing Machine

Selecting the ideal printing machine depends on multiple factors:

- Production Volume: Large volumes benefit from rotary screen or automatic screen printing, while small and customized batches favor digital printing.

- Design Complexity: Intricate or photographic designs are best suited for digital machines.

- Fabric Type: Some machines specialize in printing on synthetic or natural fibers.

- Sustainability Goals: Digital printing is more environmentally friendly.

- Budget and Space: Digital printers usually require less space and setup cost compared to traditional setups.

Future Trends in Textile Fabric Printing

The textile industry continues to innovate, with digital printing technology at the core of new trends. Developments such as faster print speeds, improved ink formulations for better colorfastness, and integration with automation and AI for optimized production are shaping the future.

Surat’s growing investment in Digital Textile Printer in Surat reflects this forward momentum, positioning the city strongly in the global textile printing landscape.

Conclusion

Textile fabric printing machines have evolved dramatically from traditional screen printing to advanced digital solutions. Each technology serves different business needs, but the rise of digital textile printing machines offers unmatched flexibility, efficiency, and sustainability. Surat’s textile industry exemplifies this evolution by embracing digital printing technologies to meet high-quality standards and market demands. Understanding the types, advantages, and future of these machines can empower businesses to make informed choices and drive innovation in textile production.